Quality Control To Quality Assurance

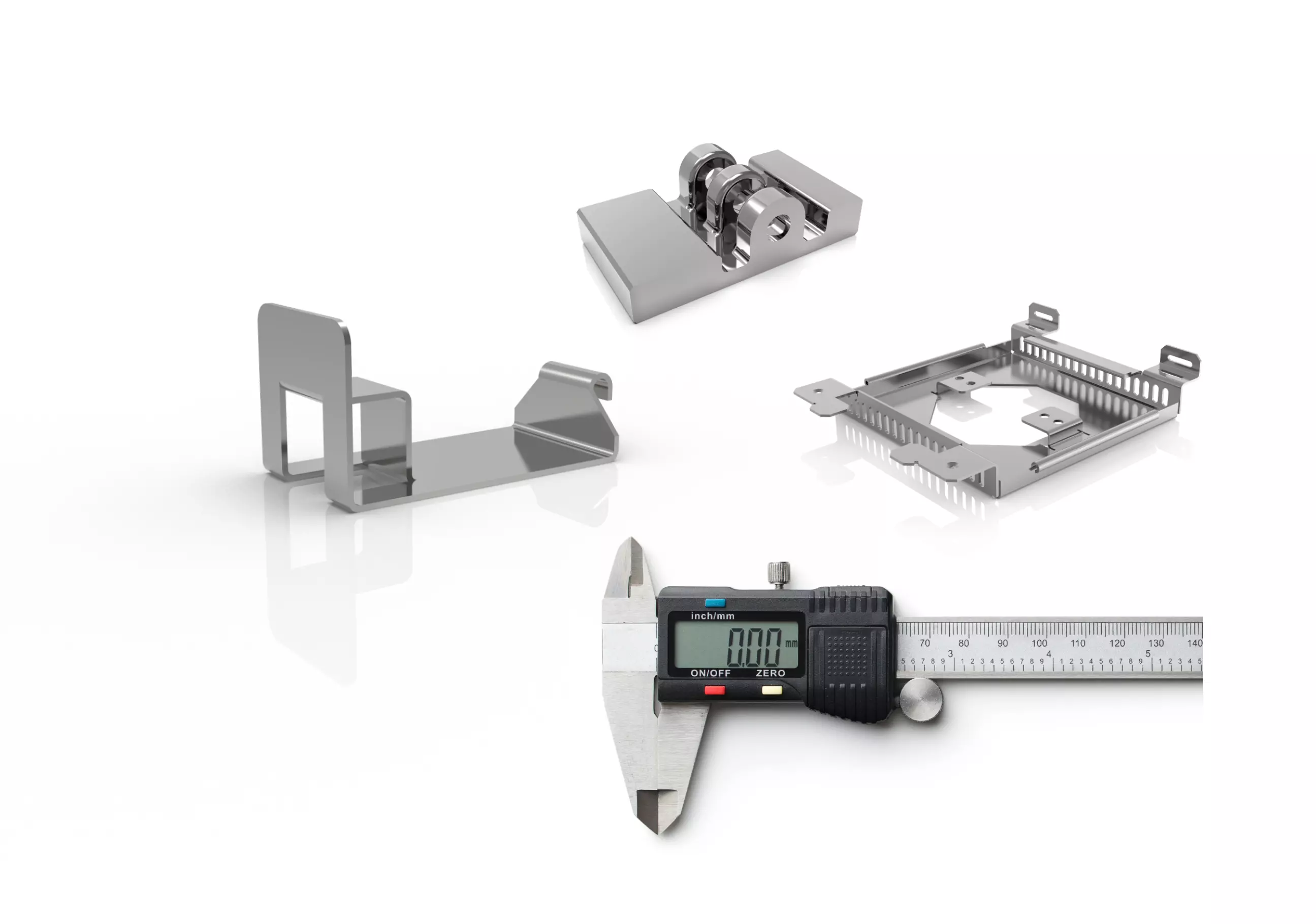

M/s Kakade Laser is focused to provide service through its robust processes and system

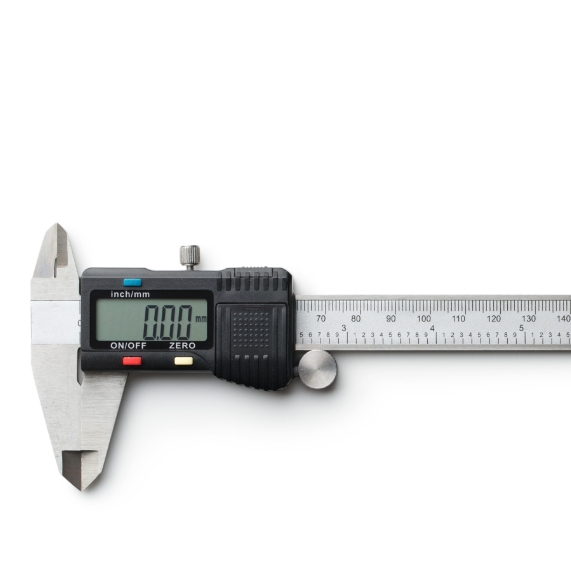

in all plants.The company has a well-equipped lab with various testing equipments like

CMM, digital height gauge and Vernier calliper to confirm and product Quality at various

stages of manufacturing. The company is continuously working towards building quality

culture in the organization.

ISO 9001 : 2015

Certification avaliable