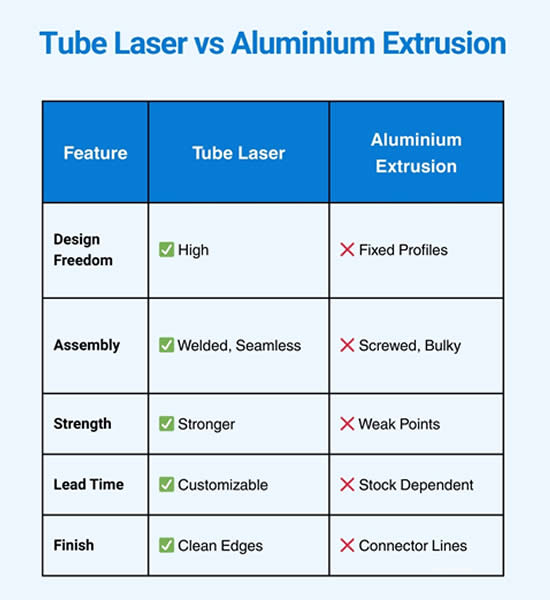

Standard aluminium extrusions are widely used across industries for frames, enclosures, and support structures. However, they often come with key limitations:

Fixed profiles and sizes

Visible joints and bulky connectors

Higher cost due to dependency on available stock

Limited strength in assembled form

These constraints reduce design flexibility and increase assembly time.

At Kakade Laser, we offer precision CNC tube laser cutting as a smarter alternative to aluminium extrusions. Recently, we recreated a 1:1 replica of an aluminium extrusion assembly using mild steel tubes—and delivered better strength, lower cost, and a cleaner look.

Custom Profiles & Openings

Welded Strength

Surface Finish Options

Reduced Lead Time

We took a customer’s aluminium extrusion-based design and rebuilt the same part using mild steel square tubes. The result:

Same dimensions and overall form

Better joint strength through welding

Fewer components and simplified assembly

Aesthetic finish through powder coating

The new version not only matched the original — it outperformed it in cost, time, and functionality.

Whether you’re working with a sketch, CAD model, or an existing assembly, our design and production teams will help you transition smoothly from extrusions to custom-cut tube components.

Client sketch or drawing

CAD modeling

CNC tube laser cutting

Welding & surface finishing

Quality check and delivery

We manufacture tube laser parts for:

Industrial machine frames

Trolleys and fixtures

Display structures

Architectural and interior applications

Control panels and enclosures

Kakade Laser, Pune | 📩 Enquire today at: salesu2@kakadelaser.in

📞 +91 9552524782 | www.kakadelaser.in