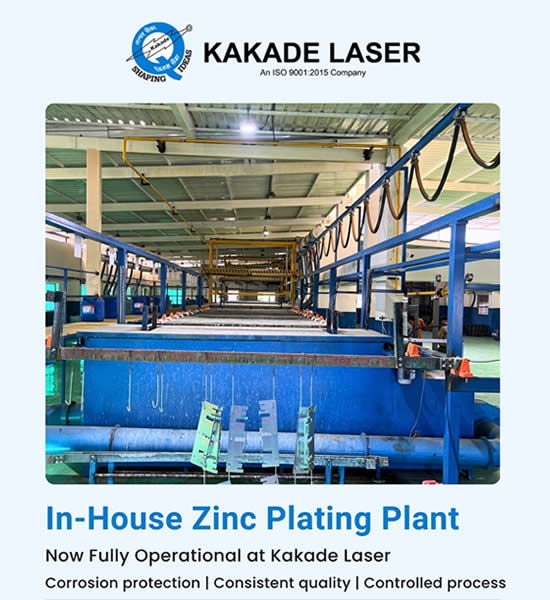

At Kakade Laser, strengthening our manufacturing ecosystem has always been a strategic priority. We are pleased to announce that our in-house zinc plating facility is now fully operational, enabling us to deliver enhanced quality control, corrosion resistance, and reduced lead times for industrial components.

This development reinforces our commitment to providing end-to-end manufacturing solutions under one roof.

Zinc plating plays a critical role in protecting metal components from corrosion while improving surface finish and service life. By bringing this process in-house, Kakade Laser eliminates dependency on external vendors and ensures complete process control.

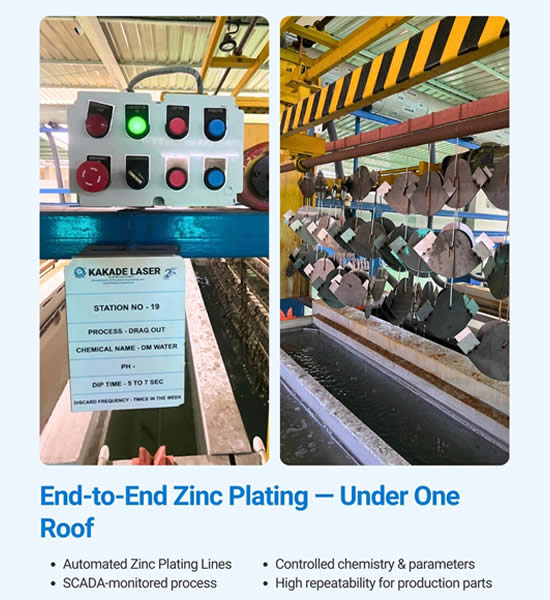

Consistent plating thickness and uniform finish

Reduced handling and transportation risks

Better coordination between fabrication and finishing

This approach results in predictable quality and improved delivery performance.

Our zinc plating plant operates with defined parameters, inspection protocols, and trained personnel to maintain consistency across batches.

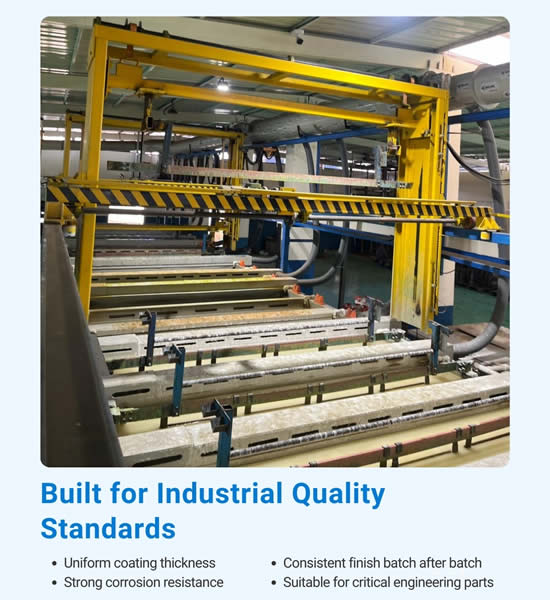

Reliable corrosion protection

Adherence to customer specifications

Batch-to-batch repeatability

Every component is processed with the same discipline and attention to detail that defines our core manufacturing operations.

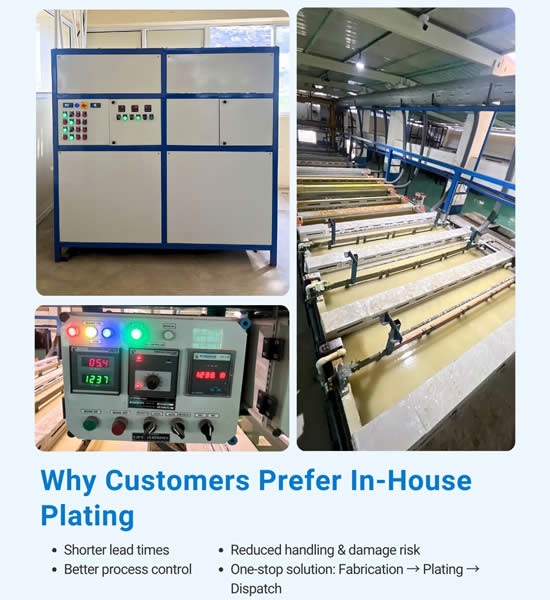

With zinc plating available in-house, production timelines are significantly optimized. Components move seamlessly from laser cutting and fabrication to surface finishing without external delays.

Time-sensitive industrial orders

Medium to high-volume production

Improved planning and scheduling for customers

Our zinc plating facility complements our existing services, creating a streamlined manufacturing workflow.

Laser Cutting and sheet metal fabrication

Precision machining and assemblies

In-house zinc plating and surface finishing

Quality inspection and controlled dispatch

This ensures customers receive ready-to-use components with consistent quality standards.

Quality control remains central to our operations. Each plated component undergoes inspection to verify finish quality and process compliance.

By managing plating internally, we take complete responsibility for performance, durability, and customer satisfaction.

Our in-house zinc plating facility supports the Make in India initiative by strengthening domestic manufacturing capabilities and reducing reliance on fragmented supply chains.

It enables us to serve automotive, industrial, and engineering sectors with greater efficiency and reliability.

If you have a zinc plating requirement for industrial or precision components, Kakade Laser is ready to support you.

📩 Send us your enquiry to discuss specifications, volumes, and timelines—our fully operational in-house facility ensures controlled quality and dependable delivery.