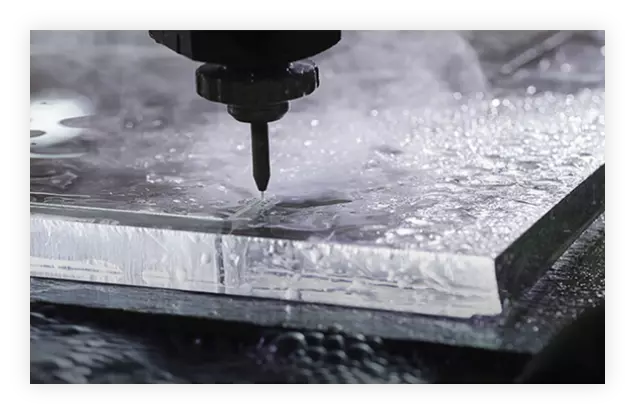

CNC Waterjet Cutting Service

Kakade laser the leading waterjet cutting service provider based in Pune, Maharashtra. We at

Kakade laser perform the engineering job work or provide job work services for both type of

manufacturing ( We provide On demand manufacturing as well as mass production for a

waterjet cutting services ). With high quality waterjet machines in Maharashtra, India we

cater the waterjet cutting services range from prototype to high-volume production runs & by

utilizing latest waterjet cutting technology we try our best to provide fast & cost-effective

solutions to our customer. Everything from titanium plate to thinnest of paper can be cut

efficiently via waterjet technology, making the potential application for this process ever

expanding. Our custom waterjet cutting services offer a cost-effective and on-demand

solution for your manufacturing needs.